1, Introduction

The Industrial Internet of Things is built on data (IIoT). Future analyses and visualizations cannot be made without data. Field device operation is ensured by remote I/O modules, which also offer a variety of distant data to boost productivity. In the industrial industry, the remote IO module is mostly used to gather analog and digital signals. It can also output analog and digital signals to control equipment. RS485 is typically utilized for transmission since the device and the primary control PLC or industrial computer may be far apart. Industrial Ethernet is also used in some factories with a high level of automation to manage remote IO modules. The Ethernet remote IO module has a quicker data collection rate, a more robust real-time performance, and more secure data.

2,

Ethernet remote IO module application case

Air Compressor Central Air Conditioner Remote Monitoring IoT Solution

Ethernet Remote IO Module is an industrial IoT solution device,special used in Air Compressor Central Air Conditioner Remote Monitoring to achieve following function:

(1

) Collect air compressor status,output compressed gas pressure and flow, dryer status, central air conditioner status, cold water flow and pressure, distribution box residual current, load current, power consumption, temperature and humidity, door status, smoke, water flooding, etc. (equipment must support Modbus protocol ).

(2

) Collect data gas pressure, gas flow, electricity, etc. on each floor.

(3

) Collect each factory fan air outlet temperature, flow and pressure ,other device or IO access

(4

) Collect the top floor exhaust fan running status, elevator overload alarm.

(5

) Stable &reliable Ethernet communication, support various data acquisition requirements, support standard Modbus TCP, MQTT protocols and customized protocols.

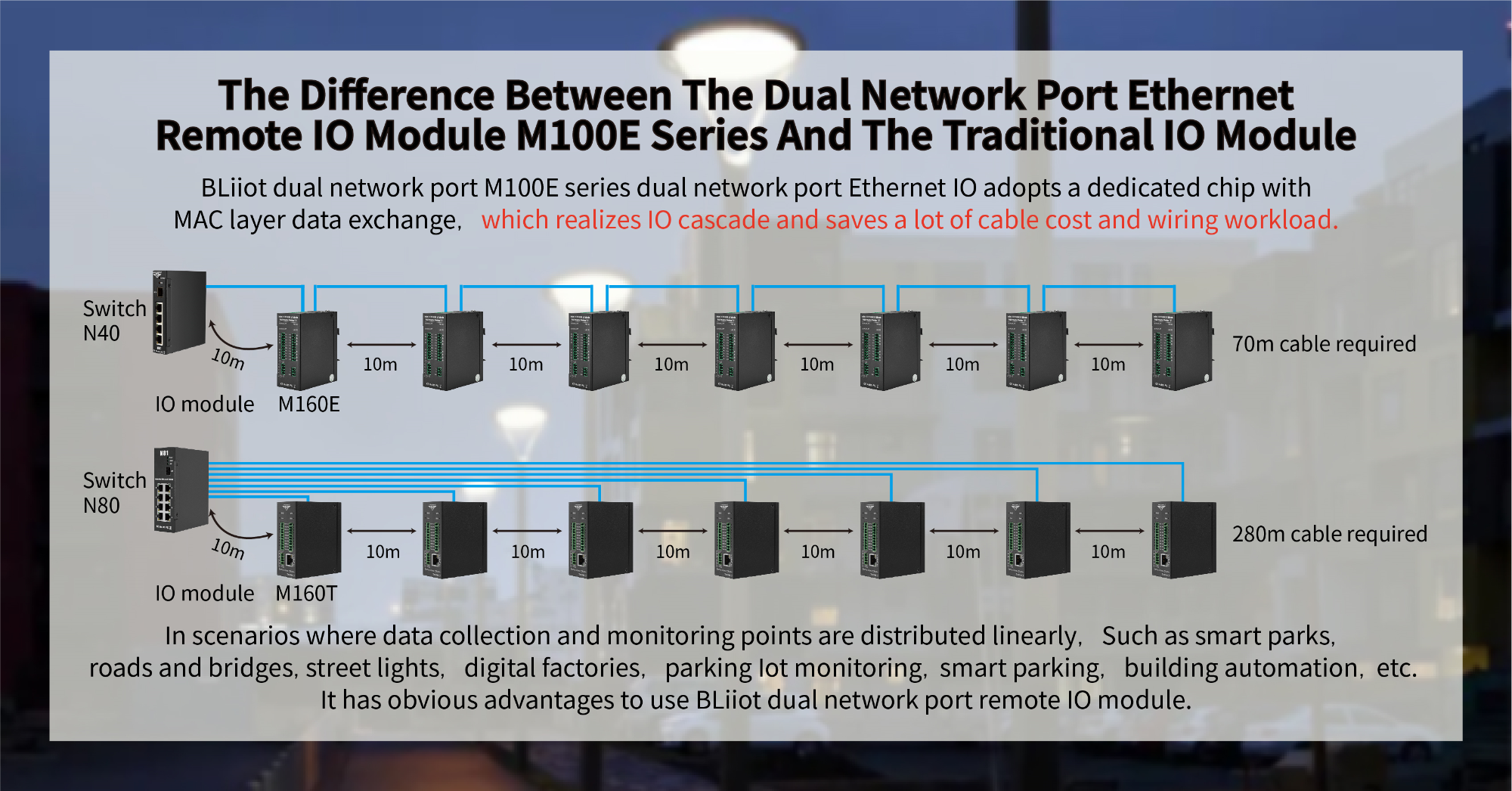

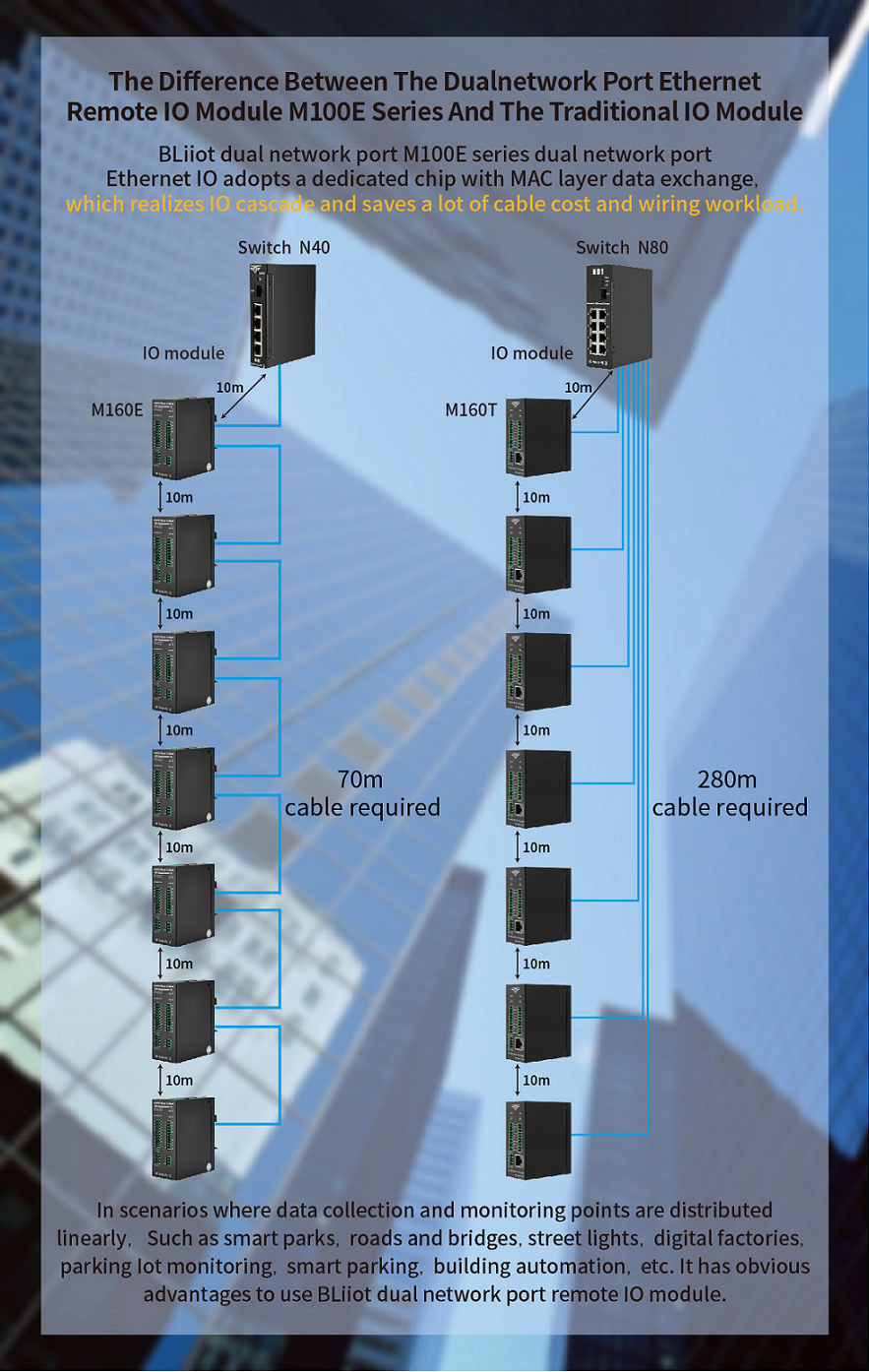

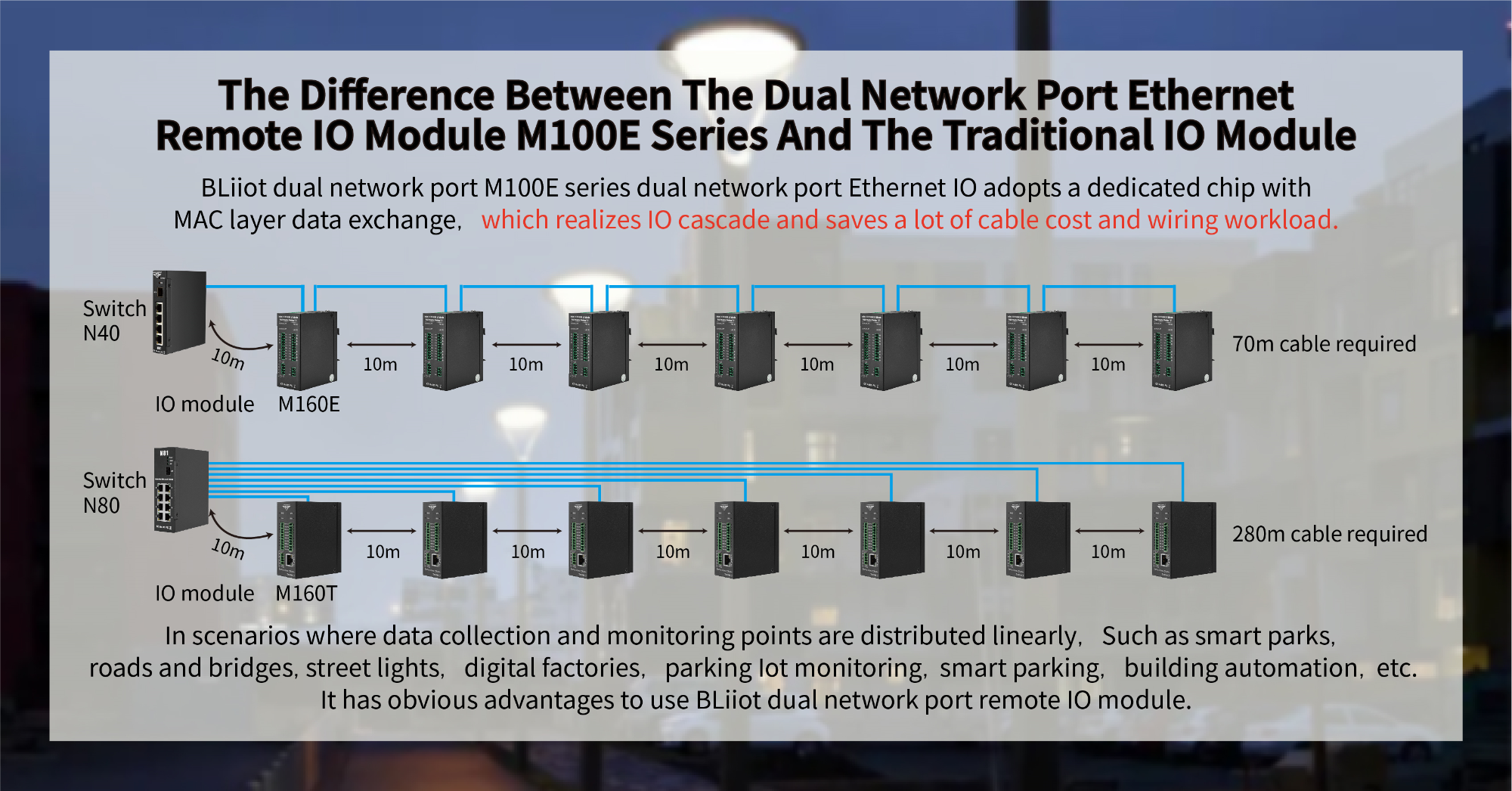

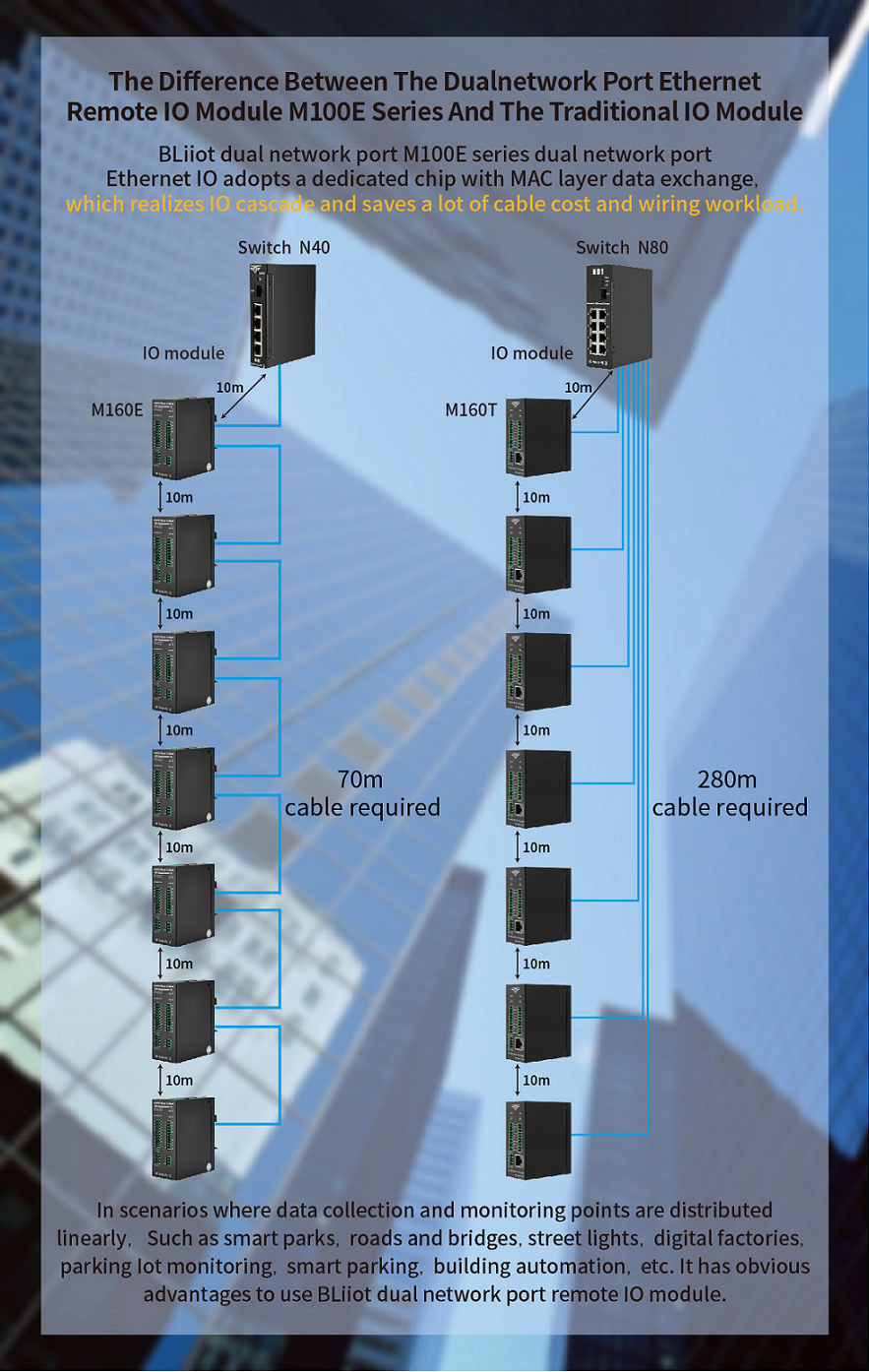

3, Dual Network Port Ethernet Remote IO Modules MXXE

MXXXE series remote IO module industrial grade design, suited for industrial Internet of things and automation control systems, MxxxE industrial Ethernet remote I/O is equipped with 2 Ethernet ports of mac layer data switching chips, allowing data to transfer over scalable daisy chain Ethernet a remote I/O array that freely travels either up to a server or down to another local Ethernet device Daisy-chained Ethernet can be used to create multi point I/O networks via regular Ethernet connections for applications including factory automation, security and monitoring systems, and tunnel communications. The most typical multi drop setups used in fieldbus solutions are well known to many industrial automation users.The MxxxE remote I/O modules' daisy-chain feature not only expands the scalability and installation options for remote I/O applications, but also lowers overall costs by eliminating the requirement for a separate Ethernet switch. Equipment can be daisy-chained in this fashion to save money on labor and wire overall.

4.Advantages of Dual Network Port Ethernet Remote IO Modules

(

(1

) No need for a large number of Ethernet switches and occupying Ethernet switch ports;

(2

) It can save a lot of Ethernet cables, cable space, and labor costs for installing cables;

(3

) The overall cost is significantly reduced;

(4

) Not only supports Modbus RTU protocol, Modbus TCP protocol, but also supports IoT protocol MQTT protocol;

(5

) Support TCP Server and TCP Client services;

(6

) It can be connected to SCADA system, PLC system or cloud platform;

(7

) The series uses the MAC layer for data exchange to ensure that the network connection will not cause communication problems with subsequent equipment due to the failure of the intermediate equipment.

Message

If you have any suggestions or question for us.Please contact us.